Distributed Sensing Technologies for Power

Distributed sensing technology has been prevalent in the power sector since the 1980s and the largest area where this technology is commonly used is in the power cable monitoring. Distributed sensing technology includes distributed temperature sensing, distributed acoustic sensing and to a lesser degree distributed strain monitoring. There are different areas, types of cables and applications covered by this technology including:

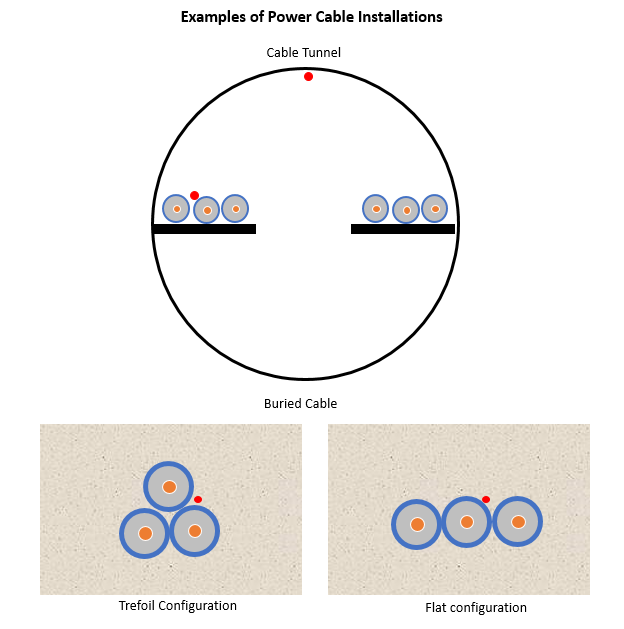

- Buried cable monitoring

- Tunnel cable monitoring

- Subsea power cable monitoring

- Overhead cable monitoring

Due to the evolution of the technology most power cable condition monitoring applications have historically been associated with distributed temperature sensing. Increasingly, however, distributed acoustic sensing is being utilized in more applications.

Distributed Temperature Sensing

The applications for distributed temperature sensing in power cable monitoring include:

- Real time thermal rating of cables (also known as dynamic cable rating). This has primarily been for buried cables, sub-sea cables and cable tunnels but there also has been applications for overhead cables

- Hot spot detection

- Fire detection for cables – this has primarily been for cable tunnels where at times there are personnel in the vicinity of the cable

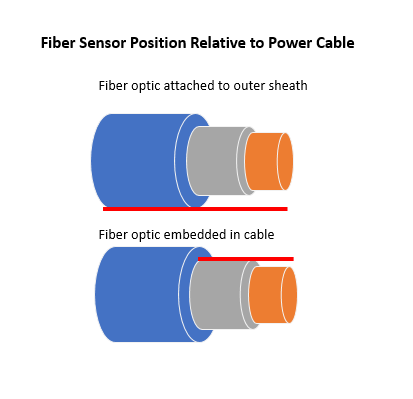

For distributed temperature sensing, one of the key factors in the configuration of the system has been the position of the fiber optic sensing cable in relation to the power cable. Ideally the DTS fiber optic sensing element would be located within the construction of the power cable itself. However, this is not always practical (either due to cable construction design or installation issues around splice joints) and so in many cases the DTS fiber sensing element is attached to the surface of the power cable configuration (or in the vicinity).

Distributed Acoustic Sensing

Distributed acoustic sensing is a more recent development but acceptance is growing quickly within the power cable monitoring segment. Some of the key applications which are building interest includes:

Asset life extension of overhead cables

Security and threat prevention for buried cables which include third party interference. This includes both accidental damage (3rd party construction) and malicious damage (terrorism, theft…..).

Security for overhead cables particularly metal theft from the towers. If a fiber optic is installed in the ground cable (OPGW), or other elements, this can detect any vibrations in the supporting framework and can pinpoint which tower is being targeted.

Galloping Power Lines

The prediction and early detection of line galloping in overhead cables due to weather events.

Fault Detection

Instantaneous fault detection and detection of partial discharge events in both buried and cable tunnels. A partial discharge event or other cable failure typically has an acoustic signature which can be located which means rapid maintenance can be carried out to minimise downtime.

The location of subsea cables. Using triangulation, of acoustic sources on the surface (boat with acoustic sounder) or seabed (acoustic beacons), the profile of the cable can be calculated and any cable movement can be measured. Preventative action can therefore be taken if the cable integrity is at risk.

Substation Condition Monitoring

The vibration and condition monitoring of substation and ancillary equipment.

Distributed Strain

Although less common than distributed temperature sensing and distributed acoustic sensing, there have been a number of applications for distributed strain monitoring, including:

Asset life extension of overhead cables

By monitoring the strain/sag of the optical ground wire and comparing versus the expected extension (vs life in service), justifications can be made to extend the lifetime of the overhead lines.

Galloping Power Lines

Dynamic strain can be measure in the optical ground wire during extreme weather events and fatigue calculations can be made vs theoretical calculations. This can be used either for life extension calculations or as part of a preventative maintenance strategy.

Power cable Installation monitoring

Based on data obtained from 28 UK offshore wind insurance losses between 2002 and 2015 with a total value of £212.7m, 68% of the losses are reported to be cable faults which occurred predominately during the construction phase. The failures were due to mechanical damage with a number of causes including over‐bending during load out and installation, excessive tension during load out and installation and crushing during post‐lay burial. By actively monitoring strain during installation – care can be taken to reduce strains and prevent mechanical damage to the cables.

Example of power cable damaged during installation

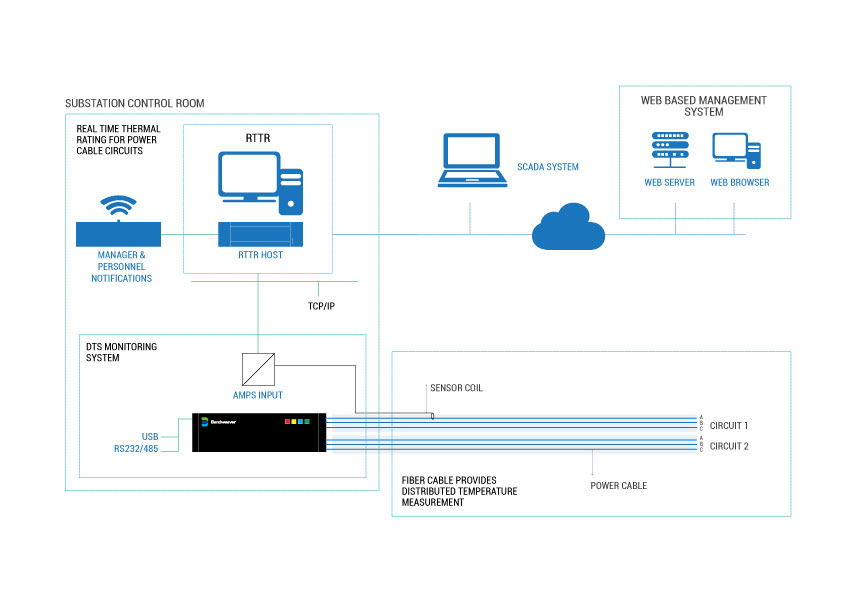

Real Time Thermal Rating

Real Time Thermal Rating is a methodology used within the power and utility sector to assess operational thermal rating of equipment. This includes assets such as:

- Underground and subsea cables

- Overhead Lines

- Transformers

In the case of power cables RTTR systems is also referred to as dynamic cable rating systems.

Real time thermal rating systems typically use real-time data taken from real environment conditions and loading rather than relying on conservative theoretical assumptions. RTTR provides additional information on system capacity (or thermal headroom). RTTR systems are able to indicate whether areas are stressed (overheated) or in fact have more capacity than originally anticipated.